|

||||||||

|

Articles about Technology

Automotives & Engineering

Biology

Chemistry

Computers, Games & the Internet

Education

General Info & Inventions

Outer Space

Physics

Robotics

Safety

Telecommunications

Handy Guide to Modern Science

Why Use A Forklift Inspection App?

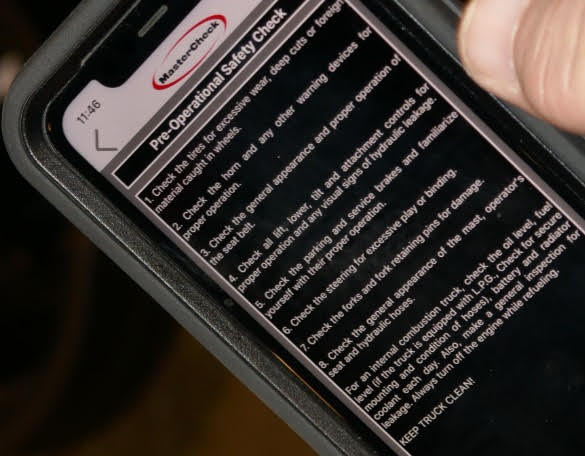

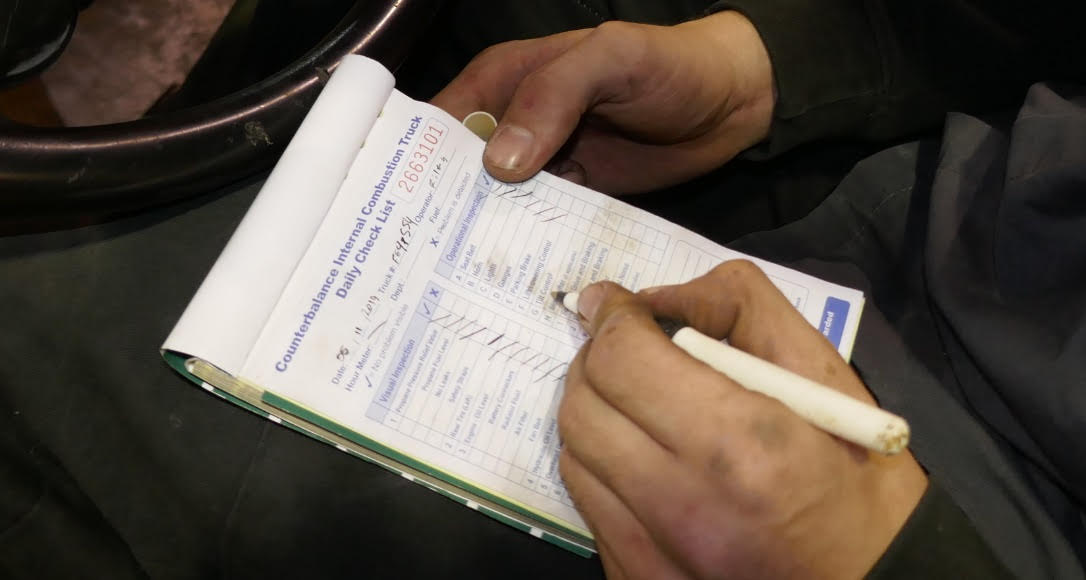

By CM - May 2020. In our ever growing direction towards robotics and paperless technology, the concept of a Forklift Inspection App was bound to happen eventually. While most people don't drive a forklift, for those people who do - and are licensed to do, because frankly forklifts are surprisingly dangerous. Forklifts in the USA kill 80 to 100 people per year and are responsible for 30,000 to 40,000 injuries per year. That is quite a bit of damage for a machine that over 99% of people don't even use. Forklift Safety Checks Forklift Safety Checks happen daily across North America. Every day, every hour, every minute. Somewhere, right now, someone is inspecting a forklift to make sure it is safe to use. So it doesn't kill or injure someone. The fact that forklifts kill 1 American every 3-4 days makes you realize why these safety measures are necessary. Forklifts kill more Americans than international terrorism. Faster, Easier, Safer

So doing these safety checks is a necessity, but there are ways to make the process easier, faster, and even safer. By using a Forklift Inspection App the operator can just press the necessary buttons instead of having write in details on a pad of paper. This saves time and paper. So there is a green environmental bonus in less trees being killed to please the paper gods. By making the process faster the whole inspection takes less time, which makes it less annoying to have to stop and do. Consequently, if the process is less annoying the operator is more likely to do it, which increases the frequency of safety checks and thus improves safety standards by having more frequent checks. A worker who is tired is less likely to want to do a proper safety check (even if they are supposed to be mandatory) and might simply tick the boxes on the paper without actually looking at the forklift. By making the process faster (and less annoying to do) it increases the likelihood that it gets done.

When I worked in a welding shop many years ago (circa 1997) I know that safety standards in that place was below par. Safety equipment was removed from machinery in order to improve speed, efficiency, and prevent waste. If a safety inspector showed up to look around the place the safety equipment was reattached just so they would pass inspection, and once the safety inspector was gone... the safety equipment was removed again. Having worked in such places I know that employers (and sometimes workers) have a very relaxed view of safety precautions. From the employers' perspective f you lose a hand it is considered to be "your fault" and not the employers' for not enforcing proper safety procedures and the use of safety equipment. I also know, because I have a friend who is a safety inspector, that safety inspectors themselves can be fired if they keep speaking up about a lack of safety and their boss decides to "let them go" because they weren't toeing the company line. If they complain about it they can also get "black listed" by potential employers and find themselves flipping burgers because they cannot find work in their profession. So clearly things need to be done to make safety inspections easier/faster for employees to do, and thus increase safety. Employers and the industry doesn't always have the workers' safety in mind. The Forklift Safety Inspection App, MasterCheck One employer who does care about his workers' safety is Gary Wilson of Toronto, Canada. Gary is the owner of Masterlift Inc, a forklift dealership he founded in 2000. In 2018 Wilson conceived and developed the forklift safety inspection app "MasterCheck", which has basically made the stationary forklift safety check forms completely obsolete. A business school graduate, 55-year old Gary understood that managers/owners were frustrated by the time-consuming task of completing the legally required pre-shift forklift inspections using paper safety check pads. The process was onerous and annoying. Suddenly inspired to find a better way, he invented the MasterCheck forklift inspection app and the system he conceived proved superior because it was so much faster, and consequently led to less people being injured.

The MasterCheck App allows employees to share reports including photos of known issues – something impossible to do with traditional paper pads inspections. The device-based methodology creates a more efficient system and provides greater clarity for ongoing issues that need to be fixed. So what is next? Honestly there are many more things out there that could be replaced by apps. The entire insurance industry for example could be replaced by apps. Auto insurance, home insurance, life insurance, dental insurance, etc. It is just a matter of time before someone like Gary Wilson comes along and creates an app that makes the whole insurance industry obsolete. Real estate agents? Potentially useful, but wait long enough and much of that industry could be replaced by an app too. Retirement fund managers? Replaced with an app that invests in the most stable and profit earning companies, based on an individual's preferences in their settings. There are lots of jobs out there that involve pushing pencils and shuffling papers around that could be replaced with an app. Basically anything involving paper documents has the potential to be replaced with software programs.

|

|

|||||||

The Sky's the Limit: How Drone Delivery Transforms the Future of Package TransportationBy Chaz G. T. Patto - June 2023. The rapid advancement of technology has opened up new possibilities for revolutionizing various industries, and package transportation is no exception. Drone delivery, once considered a futuristic concept, is now becoming a viable and promising option for efficiently transporting packages. In this article, we explore how drone delivery offers a cost-effective and environmentally friendly solution that has the potential to transform the way we receive our packages. Cost-Effectiveness and Efficiency: Drone delivery presents significant advantages in terms of cost-effectiveness and efficiency. Traditional delivery methods often involve multiple steps, including sorting, loading, and transportation via trucks or vans. Drones, on the other hand, can fly directly from a distribution center to a delivery location, bypassing the need for extensive ground transportation and reducing overall operational costs. With automated flight paths and advanced navigation systems, drones can optimize delivery routes and complete deliveries in a fraction of the time required for conventional methods. Reduced Carbon Footprint: The environmental benefits of drone delivery cannot be overstated. By minimizing or eliminating the need for fuel-consuming vehicles, drone delivery significantly reduces carbon emissions and air pollution. Traditional delivery vehicles contribute to congestion on roads and emit greenhouse gases, whereas drones operate in the airspace, reducing traffic congestion and minimizing the overall carbon footprint associated with package transportation. This environmentally friendly aspect of drone delivery aligns with global efforts to mitigate climate change and create sustainable transportation solutions. Accessibility to Remote Areas: One of the key advantages of drone delivery is its ability to reach remote or hard-to-access locations. In rural areas or regions with challenging terrain, traditional delivery methods may be costly and time-consuming. Drones can easily navigate through difficult landscapes, delivering packages to remote communities, and bridging the gap in accessibility. This opens up new opportunities for businesses to serve previously underserved areas and ensures that individuals in remote locations have access to goods and services. Safety and Security: Drone technology has advanced significantly in terms of safety and security features. With sophisticated collision avoidance systems, GPS tracking, and real-time monitoring, the risk of accidents or theft during delivery is minimized. Drones can be programmed to follow designated flight paths, avoid restricted airspace, and deliver packages securely to the intended recipients. Additionally, the use of encrypted communication and biometric authentication ensures the privacy and security of sensitive deliveries. Technological Advancements and Regulatory Framework: The future of drone delivery is not only promising but also continuously evolving. Technological advancements, such as increased battery life, improved payload capacity, and enhanced flight autonomy, are expanding the possibilities for drone applications. Furthermore, regulatory frameworks are being developed to ensure the safe integration of drones into airspace and establish guidelines for their operation. As these regulations evolve and become more streamlined, drone delivery will become increasingly commonplace. Final Thoughts: Drone delivery is poised to revolutionize package transportation, offering a cost-effective, efficient, and environmentally friendly alternative to traditional delivery methods. With its potential to reduce costs, minimize carbon emissions, reach remote areas, and enhance overall delivery efficiency, drone technology presents an exciting future for logistics. While there are still challenges to overcome, such as regulatory frameworks and public acceptance, the benefits of drone delivery make it a compelling solution that will shape the future of package transportation. As technology continues to advance, we can expect to see more drones taking to the skies, delivering our packages with efficiency, speed, and sustainability.

Touchscreen is the FutureThere may come a time in the future when you go to your coffeemaker and instead of a dial or buttons, its a touchscreen. And it will be connected via WiFi to your morning schedule, so you have the option of making your coffee "automated" and set to start say 5 minutes before your morning alarm clock goes off (which will also have a touchscreen and 100+ different buzzer tones to choose from). If you watch the Windows "Vision of the Future" video below you get a glimpse of what some of these technological innovations will look like.

That is of course assuming people want to adopt these innovations.

You see its a problem of people predicting the future. Flying cars, subway trains that go down every neighbourhood block, robots washing our dishes and doing our laundry... they may sound great but often there is serious design flaws and other hurdles to jump over first. Flying cars for example never got off the ground because they're too expensive and violated aerospace laws. People would still need a pilot's license to fly one. Subway train on every block is impractical in terms of infrastructure cost and would be an eyesore. And robots would probably break more dishes than they clean, and thus it would make more sense to just make a better dishwasher and the let the humans learn how to fill it. But that doesn't mean we can't adopt bits of new technology to items which we can easily make better. Take for example the digital camera or the TV remote. They've got a lot of buttons on them sometimes and people will often get confused about the settings and how to work them properly. A touchscreen camera or a touchscreen remote control does make a lot of sense. Indeed anything with lots of confusing buttons could be improved by having a touchscreen. Now I say digital camera for a reason, because it just so happens we now have those. Often in the form of SmartPhones that have touchscreens and a camera built in. But we also now have better quality digital cameras which use touchscreens as well, like the Samsung SH100. (Its a bit of a bargain for $249.99 Canadian, but its got some nice stuff on it, including WiFi, a video mode, lots of handy options, etc. See our review at: Egad! Digital Cameras and Video Editing.) But hey that was 2011. It just keeps getting better and better. So first satellite navigation devices, then SmartPhones, then tablet computers, now digital cameras, what is next? Well TVs with touchscreens are already here. The CBC used a touchscreen television during the May 2nd 2011 Election broadcast to demonstrate what was happening in various MP ridings. It wouldn't be a stretch to say computer monitors will be next. They already exist, but they haven't hit the mass market yet. After that it will be everything from sewing machines to fridges, pianos to dance floors... the real danger is people developing "Gorilla Arms", a condition which causes arm, neck and shoulder pain and is the result of prolonged moving of arms in weird angles in an effort to reach the touchscreen.

Spray On Clothing now a Reality By Charles Moffat - February 2012. Fashion designer Manel Torres has developed the world's first spray-on fabric that can be worn, washed and worn again. It bears the potential to revolutionize how people make clothing and what they do with their old clothing. The fabric is very cold when it is sprayed on, a limitation that may frustrate hopes for spray-on pants and other garments, but the cold disappears quickly and the end result is clothing you can use again and again. How did he do it? The fashion designer joined forces with scientists at Imperial College London in the UK to invent the spray, which forms a seamless fabric on contact with the body. It takes 15 minutes to spray a t-shirt on to a torso, the fibres dry almost instantly and can be stretched, taken off, washed, worn again, and even re-used later to make a different t-shirt if the owner wishes. How does it work? The spray consists of short fibres that are mixed into a chemical solvent, allowing it to be sprayed from a can or high-pressure spray gun. The fibres are then mixed with polymers that bind them together to form a fabric. The texture of the fabric can be varied by using wool, linen or acrylic fibres (note that this means the fibres can come from recycled sources such as your old jeans, etc). "I really wanted to make a futuristic, seamless, quick and comfortable material," says Torres. "In my quest to produce this kind of fabric, I ended up returning to the principles of the earliest textiles such as felt, which were also produced by taking fibres and finding a way of binding them together without having to weave or stitch them." Torres teamed up with chemical engineer Paul Luckham to set up Fabrican Ltd, which will explore other applications ranging from spray-on bandages, hygiene wipes and upholstery for cars and furniture. "The fashion application of spray-on fabric is a great way of advertising the concept, but we are also keen to work on new applications for the medical, transport and chemical industries," says Luckham. "For example, the spray-on fabric may be produced and kept in a sterilised can, which could be perfect for providing spray-on bandages without applying any pressure for soothing burnt skin, or delivering medicines directly to a wound."

Searching for Scientific Utopia:

By Charles Moffat - August 2009. Think of all the scientific advances that are just out of reach. Or better yet, think of all the technology we already have, but we have yet to make it affordable. Take cellphones for example. We've had the technology to make them since the 1960s, but they weren't really affordable or mass produced until the late 1990s. Now our cellphones come with a host of extra gadgets like a video camera, games, GPS, texting, internet access, music, radio and more. But we have yet to invent a more powerful / longer lasting battery. Or maybe an alternative way to recharge the battery. Quite a few companies have come out with solar adapters for cell phones which people can either carry with them or leave in their car. Or better yet, a cell phone with its own solar cells. Next lets discuss housing. We are still using the same building technology we've been using for hundreds of years. Wood, brick, mortar and cement. Depending on the building we also use steel and glass... and glass is a very good insulator. When it comes to housing it is all about insulation. So what we need is a new kind of insulation, or we need to think backwards and build using more stone (which is a great insulator). Food wise we now have genetically modified foods, although the growing trend is towards natural organic foods (without pesticides) that are grown in greenhouses and controlled environments. Which brings us back to building technology again. We need to be mass producing more greenhouses, especially in regions which have a shortage of locally grown food. The world also has a growing shortage of fresh / clean water. So what we need is a way to cheaply distill / filter salt water and make water that is safe to drink. This technology could also be used to recycle water. After that its just a matter of transporting water to locations that need it.

On top of this it would be nice to have more technology to conserve water. How about really tiny dishwashers? I think there is a market for a dishwasher about the size of a microwave, one that fits easily on the kitchen counter. That covers food and water, but what about health care? Think of all the advances we've had in the last hundred years of medicine. Its safe to assume we will make a good portion more advances in the next 20 years. Lets take AIDS medicine for example. Anti-retrovial medicine has reached a point where AIDS/HIV is basically cured, but the medicine is quite expensive. Over time however the price of those medicines should come down. Part of the problem is not scientific, but just plain greed. The American pharmaceutical industry is more worried about their stock value and trillion dollar profits than actually treating people. Outside of medicine new techniques and procedures for curing ailments, surgeries and such are continuing to make improvements. The sad fact however is that many Americans lean towards the quick fix, when in reality what they really need is more exercise and proper diet. Not much can be done to prevent health problems if people don't take care of themselves in the first place. Extending life span is also within our reach as tests on a variety of hormones like HGH (Human Growth Hormone) show promising signs of maintaining a person's youthful appearance and increases our recuperative abilities. We may soon find a combination of hormones or a drug which allows humans to live significantly longer. Failing that we now have robotic hearts, robotic limbs and robotic technology is quickly becoming a global industry. Leading the way is Japan where they are already experimenting with robotic soldiers (Mechs), robotic massage parlours and robots for essentially every menial task. Imagine 20 years from now walking into a McDonalds that is 100% automated, voice activated and serves up the food faster than a human could ever do. (Which leaves us humans doing all the jobs which require creative, managerial or maintenance skills.)

One of the biggest changes we will likely see will be in the automotive industry. Hydrogen cars are coming and within 10-15 years gasoline and diesel cars will be obsolete. Along with that we can expect cars to get more complicated as GPS, computers, auto-pilot technology and other fancy bits become more common. 60 years ago the fastest road-legal car in the world was the Jaguar XK120. The 120 in the name was for its top speed of 120 mph (193 km/h). In 2009 the fastest road-legal car is the Gumpert Apollo Sport... The Ascari A10, Koenigsegg CCX TGW, Pagani Zonda F Roadster, Caterham Seven R500 and the Bugatti Veyron are arguably just as fast around a race track and collectively have top speeds of approx. 400 km/h (250 mph). What this tells us is that the top speed of road-legal cars has more than doubled in the last 60 years. So in the next 20 years we might expect a road-legal car to have a top speed of 677 km/h (421 mph). We also should expect to see more variety on the road. Electric bicycles are becoming quite popular and more affordable. I also predict people buying GPS tracking with their bicycles to prevent theft. Right now bicycles are the most popular vehicle of transportation in the world, a total of approx. 1.5 billion bicycles. There is approx. 700 million cars, trucks, motorcycles and other automobiles on the road in 2009. By 2020 its estimated there will be 820 million automobiles. A Russian company is currently working on a plane that is expected to replace the ol' British Concorde planes (only 20 were ever built, cruising speed of Mach 2.02 and they were retired from service in 2003). The TU-244 being built by Russian company Tupolev has a set goal of Mach 3 and will be set for launch in 2015.

For aerospace there is also the matter of the NASA space shuttle which will be retired in 2010, after 31 years of ferrying astronauts back and forth from Earth's orbit. To replace the space shuttle NASA (and international partners from 15 other nations) are planning to a Crew Exploration Vehicle (CEV) capable of performing the same tasks the space shuttle did, but also of landing on the moon and traveling to Mars as part of Project Constellation. As of August 2009 we have two functioning robots on Mars: the Spirit rover and the Opportunity rover. By 2012 there will be 4 more missions by the United States, Canada, Russia and China to collect soil samples and send back info to earth. Because Mars' and Earth's orbits are different the optimal launch windows to Mars are every 780 days. NASA has plans to begin terraforming Mars by 2030 and manned colony missions by 2040. Russia and China have made similar claims, but all three are subject to budgetary restraints rather than technology. In recent years there has also been a significant rise in space tourism and many independent companies building their own smaller space shuttles with plans to ferry people into orbit, give them a tour of a couple hours, and then return back to earth. The technology is there and its certainly profitable, but it doesn't really serve a logical purpose beyond helping to expand scientific research in the field of aerospace. Conclusions? We are so close to having all the food, water, shelter, medicine, transportation, robots and clean energy we could ever want. With some time and investment we could be living in a technological utopia.

Becoming Invisible Invisibility has been on humanity's wish list at least since Egyptian times. With recent advances in optics and computing however, this elusive goal is no longer purely imaginary. Last spring, Susumu Tachi, an engineering professor at the University of Tokyo, demonstrated a crude invisibility cloak. Through the clever application of some dirt-cheap technology, the Japanese inventor has brought personal invisibility a step closer to reality. Tachi's cloak - a shiny raincoat that serves as a movie screen, showing imagery from a video camera positioned behind the wearer - is more gimmick than practical prototype. Nonetheless, from the right angle and under controlled circumstances, it does make a sort of ghost of the wearer. And, unlike traditional camouflage, it's most effective when either the wearer or the background is moving (but not both). You don't need a university lab to check it out: Stick a webcam on your back and hold your laptop in front of you, screen facing out. Your friends will see right through you. It's a great party trick. Such pathetic parlor trick demonstrations aren't going to fool anyone for more than a fraction of a second. Where is Harry Potter's cloak, wrapped around the student wizard as he wanders the halls of Hogwarts undetected? What about James Bond's disappearing Aston-Martin in Die Another Day? The extraterrestrial camouflage suit in the 1987 movie Predator? Wonder Woman's see-through Atlantean jet? It's not difficult to imagine a better system than Tachi's. In fact, invisibility that would satisfy any wizard - not to mention any spy, thief, or soldier - is closer than you might think. US Defense Department press releases citing "adaptive," "advanced," and "active" camouflage suggest that the government is working on devices like this. If so, it's keeping them under wraps. However, NASA's Jet Propulsion Laboratory has published a preliminary design for an invisible vehicle, and battalions of armchair engineers have weighed in with gusto on newsgroups and blogs. As it happens, most of the schemes that have been advanced overlook the complexities of the problem. Invisibility isn't a simple matter of sensors that read the light beams on one side of an object and LEDs or LCDs that reproduce those beams on the other. In fact, such a system would work about as well as the laptop party trick with the webcam's lens removed: Objects right up against the sensors would produce blurry images on the display, but a few centimeters away they'd disintegrate into a featureless gray haze.

An invisibility cloak, if it's going to dupe anyone who might see it, needs to represent the scene behind its wearer accurately from any angle. Moreover, since any number of people might be looking through it at any given moment, it has to reproduce the background from all angles at once. That is, it has to project a separate image of its surroundings for every possible perspective. Impossible? Not really, just difficult. Rather than one video camera, we'll need at least six stereoscopic pairs (facing forward, backward, right, left, upward, and downward) - enough to capture the surroundings in all directions. The cameras will transmit images to a dense array of display elements, each capable of aiming thousands of light beams on their own individual trajectories. And what imagery will these elements project? A virtual scene derived from the cameras' views, making it possible to synthesize various perspectives. Of course, keeping this scene updated and projected realistically onto the cloak's display fabric will require fancy software and a serious wearable computer. Many of the technical hurdles have already been overcome. Off-the-shelf miniature color cameras can serve as suitable light sensors. As for the display, to remain unseen at a Potteresque distance of, say, 2 meters, the resolution need not be much finer than the granularity of human vision at that distance (about 289 pixels per square centimeter). LEDs this size are readily available. Likewise, color isn't a problem - 16-bit displays are common and ought to suffice.

But it will take more than off-the-shelf parts to make the cloak's image bright enough to blend in with the daytime sky. If the effect is to work in all lighting conditions, the display must be able to reproduce anything from the faintest flicker of color perceptible to the human eye (1 milliwatt per square meter) to the glow of the open sky (150 watts per square meter). Actually, the problem is worse than that: According to Rich Gossweiler at HP Labs, the sun is 230,000 times more intense than the sky surrounding it. If we want the cloak to be able to pass in front of the sun without looking hazy or casting shadows, we'll need to make it equally bright. Of course, this would put severe demands on the display technology - LEDs just ain't that brilliant - and it would increase battery size or shrink battery life accordingly. So let's ignore the sun and take our chances. An average TV screen looks blank in full daylight, so we'll need something brighter, more along the lines of a traffic light. Another problem is response time. Like a TV screen, the cloak's display must be able to update faster than the eye's ability to perceive flickering. It has to register motion in real time without the blurring, ghosting, smearing, and judder that plague today's low-end monitors. A laptop LCD screen isn't going to cut it. A lattice of superbright LED microarrays probably will. The real challenge however is turning the video images into a realistic picture. The view from a pair of cameras strapped to your body is different from the perspective of an observer even a short distance away. The observer can see things the cameras can't, thanks to parallax - the way the angles change with the distance.

TeraGo Networks Cloud Services Business Center: Where Data Lives

Recently the Toronto tech community has been buzzing about TeraGo Networks Cloud Services Business Center in Mississauga. The excitement is due in part to an Open House event that happened on the 14th of May 2015 which brought in a couple hundred IT managers, photographers and reporters from the ever expanding Brampton Toronto tech corridor where the new facility is located. TeraGo Networks Cloud Service for business was featured on Backbone Magazine blog last week and the Cloud Service Center Open House was in Toronto is Awesome the week before that. The #WhereDataLives event was designed to showcase the enormous facility that was originally designed by Blackberry. The location was profiled by Nikki Fotheringham in Greenmoxie: Green Clouds In Canada. At 4 pm the doors opened and attendees entered the space and selected nutritious snacks from among a vast array of bite-sized cuisine carried about on polished wooden trays. The smell of freshly toasted nibbles filled the facility as over one hundred guests mingled about in a sunny reception area that was decorated with tall trees lit from below with purple LED sconces - a nice effect. CityEvents dressed in a few high-top tables and chairs on the periphery of the affair, but elected not to fill the room with folding chairs thus encouraging livelier networking. The SURROUND Internet Marketing Agency blog post Party in the Cloud detailed some of the logistics surrounding of the special event.

TereGo Networks Open House featured two notable speakers, the first was TeraGo Networks CEO and President Stewart Lyons, who was followed by Philbert Shih of Structure Research. These dignitaries gave an overview of the industry and highlighted TeraGo's many offerings - the firm provides a broad suite of server, storage and network services with extensive granularity. This enables users to leverage the cloud for many reasons ranging from small developer tests to high performance, high availability platforms supporting mission critical applications.

Where Data Lives

Most folks came because they were genuinely curious about the Twitter hashtag #WhereDataLives; they really wanted to see where their data is stored (or will be stored), and try to get a better grasp of what's involved in the business of offering cloud services in Canada. After signing up for the tour, participants were issued group numbers and small white cards with cryptic messages like, 'At 5:15pm meet at the elevator bank“. It felt like a scavenger hunt and instilled excitement in all attendees anticipating discovering for themselves a truly forbidden place. The tour times were accelerated by Deb Lewis of City Events. After Phil's speech she came over the airwaves and called for the tours to get started right away which caused some happy confusion at the elevators as big groups had to break apart and rendezvous again in the lobby before leaving the building to stroll about the grounds and behold the external power facilities. Having a constant supply of electricity is extremely important to data centers of course, as the cloud can never go dark or service will be lost, and that’s unacceptable to any online business that wants to stay in business online. IT World Canada wrote an article about TeraGo Networks Data Center outlining the elements of the facility including the power station at the back of the building. A white concrete shed at the rear of the building hosts ten 600 kVa generators currently sitting idle but which can be running full throttle and generating power at maximum capacity in less than two minutes. The facility has state-of-the-art UPS or Uninterrupted Power Supply technology which provides high density, true double-conversion on-line power protection for servers, voice / data networks.

With cabling up top and power below its a clean looking room, even when lit with strange purple LED lights. The interior of the cabinet room has been laid out in a warm aisle, cold aisle configuration with 2N cooling infrastructure that includes chilled water towers and closed glycol loop, and independent air-cooled rooftop cooling units and fourteen 30-tonne CRAC units, supporting 1470 kVa.

TeraGo ensures all your data is stored in the right environment. Every cabinet includes both A and B power and can support up to 42 rack units each. The railings are depth adjustable, allowing tenants to customize the space needed for their equipment. TeraGo Network's new Mississauga data center is a Tier 3 capable facility equipped with 2N power, cooling and connectivity infrastructure, to provide very high levels of reliability, and they pride themselves on customer support and security. TeraGo Networks ensures your business data has never been more secure. Article by Robert Campbell, 27 May 2015

|

||||||||

|

|

||||||||